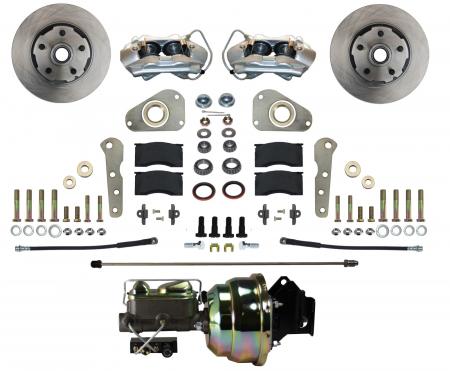

Wilwood Brakes Compact Tandem M/C Kit with Bracket and Valve 261-14963-P

Wilwood has packaged the new Compact Tandem Chamber Master Cylinder with the Combination Proportioning Valve, L/H mounting bracket, fluid tubes and mounting hardware in a kit. Tandem Master Cylinder represents the latest in refinements in brake pressure actuation and fluid control in a compact package with only 6.55" from mounting flange to end. The slotted flange mounting makes it a simple bolt on for many OE mounts including the popular Chrysler, Corvette, GM, and Ford Mustang bolt patterns and is compatible with manual or power brake system applications. Master cylinders without pushrods are generally intended for power brake use and available in two bores sizes, 1.00” or 1-1/8”, and two finishes, ball burnished or black E-coat. The combination proportioning valve substantially simplifies wiring and brake proportioning adjustments on vehicles with custom brake systems. The combination block maintains full isolation between front and rear fluid circuits and is specifically designed to accompany the Tandem Chamber Master Cylinder. The combo valve and left-hand side bracket are black E-coated for a performance look and long lasting durability. Stainless steel fluid tubes are precision bent with preinstalled plated steel tube nuts for a simple bolt-on installation between the Combination Proportioning Valve and the Wilwood Tandem Master Cylinder. Stainless steel button head fasteners thread into the bracket for a simple installation and years of durable, rust-free performance. Simply connect the fluid lines, bleed the system, and you're finished.

Wilwood Engineering designs and manufactures high-performance disc brake systems. Since the company’s inception in 1977 by Bill Wood, we have developed a substantial matrix of brake components and engineering techniques that allow us to quickly and reliably create brake systems for almost any application. Our core ability is the rapid development of custom engineered brake systems using a combination of off-the-shelf and custom components. In addition to designing and manufacturing brakes for all types of competitive motor sports, Wilwood also manufactures brake systems and components for agricultural equipment, industrial applications, utility vehicles, snowmobiles, quads, motorcycles and military vehicles.

With headquarters in Camarillo, California, Wilwood employs approximately 250 people. We have on-shelf stock of more than 300 different brake calipers, 200 rotor designs, 100 master cylinder designs and a wide assortment of brackets, fittings, valves and brake lines. Our off-shelf brake calipers range in size from tiny calipers used on go-carts and light duty industrial equipment, to heavy duty original equipment brakes for the U.S. military Humvee.

Wilwood's engineering department uses the latest computer-aided design and manufacturing techniques in conjunction with finite element analysis, dynamic test and cycle test equipment, to find high-performance and reliability solutions for the most difficult braking tasks. Our extensive inventory of proprietary on-the-shelf components allow us to provide cost-effective solutions for unique brake applications.

Wilwood is ISO 9000 compliant and has extensive experience maintaining quality levels of 100ppm or less for original equipment manufacturers.

Specifications:

| Master Cylinder Dimensions | |

| Area (in²) | 0.780 |

| Bore Size | 1.00" |

| Stroke | 1.10 |

| Master Cylinder Description | |

| Finish | Media Burnished |

| Material | Aluminum |

| Outlets | 2 |

| Type | Tandem Outlet |

| Additional Dimensions | |

| Flange to End Length (in) | 6.55" |

| Outlet Fit 1 (in) | 3/8-24 IF or 1/2-20 IF |

| Outlet Fit 2 (in) | 3/8-24 IF or 9/16-18 IF |

| Outlet Size 1 (in) | 1/2-20 |

| Outlet Size 2 (in) | 1/2-20 |

| Overall Length(in) | 7.16" |

| Product Documents | |

| Rebuild Kit | Product Data Sheet |

| Reservoir | |

| Res Size (oz) | 7.8 / 4.7 |

| Res Size(cu in) | 14.0 / 8.5 |

| Res Type | Integral |