VB-4, Flexible Floor Barrier, 1 Pack, (37 x 54)

VB-4 is a composite product that has been engineered to block and reflect high energy, low frequency road noise, an airborne sound, across a wide frequency range. VB-4 consists of a closed cell neoprene foam layer that is bonded to a dense 1lb ft² vinyl barrier.

How does VB-4 work?

The neoprene foam layer creates an "airsping" that floats or decouples the dense layer of vinyl. It is this airspring that allows for the reflection of high energy soundwaves and prevents the sound energy from passing through the dense layer. The foam layer does not absorb sound nor does it "filter" because it is far too thin to absorb high energy, low frequency sound waves. Be wary of any company that promotes a barrier material in this way.

Conversely, VB-4 will prevent sound energy from escaping the vehicle which may be of particular interest to those of you who compete in car audio competitions.

Where do I use VB-4?

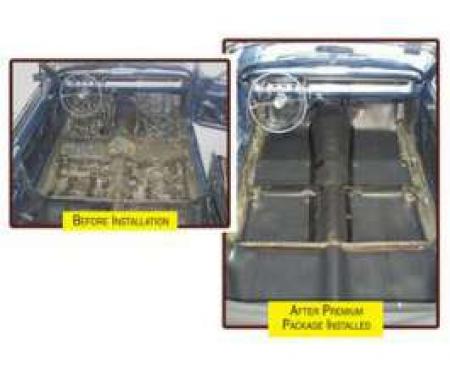

VB-4 is used primarily on flat areas of the floor pan and on the floor of the trunk or cargo area. VB-4 is installed onto the floor pan with the neoprene foam side down facing the floor pan.

Why should I use a floating barrier and not multiple layers of a vibration damper?

A common misconception is that vibration damping sheets are designed to block road noise, an airborne sound problem. Although this technique can yield a reduction in the overall noise floor, it requires 4-6 layers of material which will increase the cost, installation time and dramatically increases the amount of weight added to the vehicle. Save yourself a lot of time, money and hassle by using a dedicated "floating" barrier material first.

VB-4 weighs 1lb ft² and is equivalent to 6 layers of a vibration damping sheet.