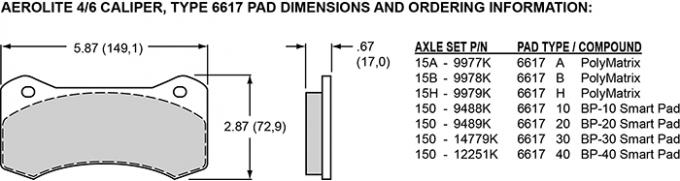

Quick-Silver series W4AR nickel plated forged billet four piston calipers provide matched bias rear braking for use in conjunction with the W6AR front calipers. W4AR calipers incorporate race technology into a radial mount body design with widespread adaptability and an expanded rotor compatibility range from 12.19” to 15.00”, including update options for all W4AR Big Brake kits. Stainless steel pistons, high-temp seals, SRS bridge plates, and two-piece bleed screw assemblies are standard in all calipers. Two high performance street, and four high-temp race only brake pad compounds in the 6617 pad type, allow precise tuning of the brake response, friction requirements and temperature range for all types of high performance and competition applications.

The W4A body is the product of FEA computer design and stress flow forging technology. FEA technology allows the designer to test the prototype in a computer environment to determine the optimal structural design within the dimensional parameters of the component. Stress flow forging produces a part with the internal grain structure of the metal aligned in the direction of the flow of the body contour. The results are a caliper with superior clamping efficiency and ultimate strength against fatigue, stresses, and distortion under load.

The performance of the W4A is enhanced with SRS bridge plates, snap-ring locked pad retainer pins, recessed two-piece bleed screw assemblies and dampen mounted fluid transfer tubes. SRS bridge plates eliminate all bridge wear caused by pad gouging. The spring-loaded action of the plates also eliminates pad rattle. Snap ring clips lock the pad pins in place to provide positive retention and allow easy service without caliper removal. The bleed screws are recess mounted for protection against impact and debris. The fluid tubes are dampen mounted to protect them from fatigue or damage from vibration or debris.

About Wilwood Engineering

Wilwood Engineering designs and manufactures high-performance disc brake systems. Since the company’s inception in 1977 by Bill Wood, we have developed a substantial matrix of brake components and engineering techniques that allow us to quickly and reliably create brake systems for almost any application. Our core ability is the rapid development of custom engineered brake systems using a combination of off-the-shelf and custom components. In addition to designing and manufacturing brakes for all types of competitive motor sports, Wilwood also manufactures brake systems and components for agricultural equipment, industrial applications, utility vehicles, snowmobiles, quads, motorcycles and military vehicles.

With headquarters in Camarillo, California, Wilwood employs approximately 250 people. We have on-shelf stock of more than 300 different brake calipers, 200 rotor designs, 100 master cylinder designs and a wide assortment of brackets, fittings, valves and brake lines. Our off-shelf brake calipers range in size from tiny calipers used on go-carts and light duty industrial equipment, to heavy duty original equipment brakes for the U.S. military Humvee.

Wilwood's engineering department uses the latest computer-aided design and manufacturing techniques in conjunction with finite element analysis, dynamic test and cycle test equipment, to find high-performance and reliability solutions for the most difficult braking tasks. Our extensive inventory of proprietary on-the-shelf components allow us to provide cost-effective solutions for unique brake applications.

Wilwood is ISO 9000 compliant and has extensive experience maintaining quality levels of 100ppm or less for original equipment manufacturers.