Wilwood’s Billet Narrow Mount Dynalite (NDL) Radial Mount caliper series continues to grow in popularity over a wide range of racing and high performance applications. Starting at 2.70 pounds, this compact and lightweight proven performer is now available in a radial mount configuration. The Billet NDLR calipers can be directly mounted over studs, or used with a radial mount bracket kit in place of a tab mount caliper.

The Billet NDLR caliper is a compact, lightweight, and rugged caliper that provides strong clamping force from four 1.75" stainless cup pistons. The bodies are fully CNC machined from billet with internal fluid ports that eliminate external fluid tubes. Each caliper is equipped with four corner bleeds to accommodate mounting in all positions. The bridges are equipped with stainless steel anti-rattle wear plates. These plates reduce bridge wear and provide smooth, rattle free operation of the pads. A center bridge bolt adds overall caliper strength and positive retention of the top loaded pads.

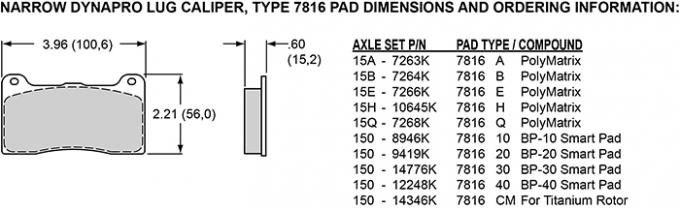

All Billet NDLR calipers are designed for long service using the 0.63” (16,0 mm) thick 7216 style brake pads. These pads are available in eight different PolyMatrix compounds to provide the correct brake torque and heat range for any high performance or competition application.

Additional Notes

Radial mount bracket kits are used to install a radial mount caliper in place of a tab mount caliper. NDLR brackets use the popular 3.50" mount pattern found on Wilwood SL, NDL, and many other popular racing calipers. On applications where the tab mount bolts are difficult to access, radial mounting can drastically simplify service in the field. Radial brackets also provide two planes of adjustment for precise alignment over the disc. Wilwood’s unique Thermlock® T1 Short Track Piston is an optional feature on our Billet NDL calipers.

About Wilwood Engineering

Wilwood Engineering designs and manufactures high-performance disc brake systems. Since the company’s inception in 1977 by Bill Wood, we have developed a substantial matrix of brake components and engineering techniques that allow us to quickly and reliably create brake systems for almost any application. Our core ability is the rapid development of custom engineered brake systems using a combination of off-the-shelf and custom components. In addition to designing and manufacturing brakes for all types of competitive motor sports, Wilwood also manufactures brake systems and components for agricultural equipment, industrial applications, utility vehicles, snowmobiles, quads, motorcycles and military vehicles.

With headquarters in Camarillo, California, Wilwood employs approximately 250 people. We have on-shelf stock of more than 300 different brake calipers, 200 rotor designs, 100 master cylinder designs and a wide assortment of brackets, fittings, valves and brake lines. Our off-shelf brake calipers range in size from tiny calipers used on go-carts and light duty industrial equipment, to heavy duty original equipment brakes for the U.S. military Humvee.

Wilwood's engineering department uses the latest computer-aided design and manufacturing techniques in conjunction with finite element analysis, dynamic test and cycle test equipment, to find high-performance and reliability solutions for the most difficult braking tasks. Our extensive inventory of proprietary on-the-shelf components allow us to provide cost-effective solutions for unique brake applications.

Wilwood is ISO 9000 compliant and has extensive experience maintaining quality levels of 100ppm or less for original equipment manufacturers.