Wilwood Brakes Forged Superlite 4 Radial Sprint Inboard Rear Brake Kit 140-15815

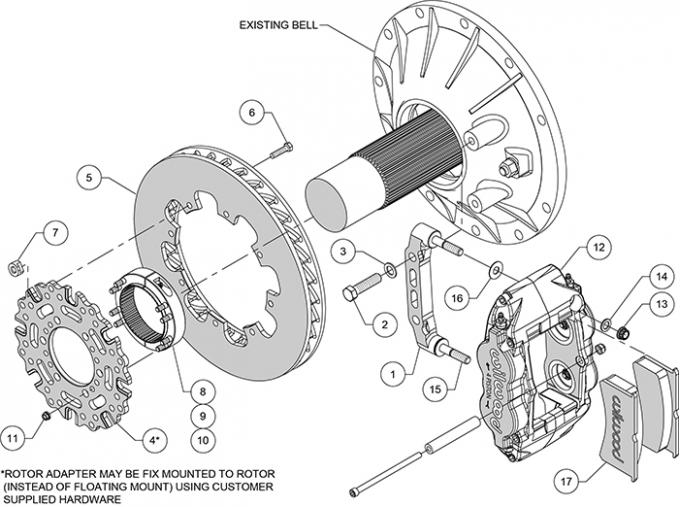

Forged Superlite 4 Radial Sprint Inboard Kit Features: A fully engineered bolt-on brake system for sprint car quick change rears with 3.00 x 46 splined axles. With 12.19" x 1.25" Super Alloy vented rotor and a newly designed dynamic mount rotor axle clamp, offer the lowest rotating weight available for Sprint racing. The lightweight advantages of Wilwood Sprint rotors are fortified with the high durability, long wear, and superior heat control properties of advanced materials. Newly redesigned Type III hard anodize Forged Superlite 4 Radial mount calipers with BP-40 pads, produce superior stopping power and consistent fade-free response. Kit includes Axle Clamp with Dual Mount Rotor Adapter with T-nuts, radial mount bracket assembly and mounting hardware.

Wilwood Engineering designs and manufactures high-performance disc brake systems. Since the company’s inception in 1977 by Bill Wood, we have developed a substantial matrix of brake components and engineering techniques that allow us to quickly and reliably create brake systems for almost any application. Our core ability is the rapid development of custom engineered brake systems using a combination of off-the-shelf and custom components. In addition to designing and manufacturing brakes for all types of competitive motor sports, Wilwood also manufactures brake systems and components for agricultural equipment, industrial applications, utility vehicles, snowmobiles, quads, motorcycles and military vehicles.

With headquarters in Camarillo, California, Wilwood employs approximately 250 people. We have on-shelf stock of more than 300 different brake calipers, 200 rotor designs, 100 master cylinder designs and a wide assortment of brackets, fittings, valves and brake lines. Our off-shelf brake calipers range in size from tiny calipers used on go-carts and light duty industrial equipment, to heavy duty original equipment brakes for the U.S. military Humvee.

Wilwood's engineering department uses the latest computer-aided design and manufacturing techniques in conjunction with finite element analysis, dynamic test and cycle test equipment, to find high-performance and reliability solutions for the most difficult braking tasks. Our extensive inventory of proprietary on-the-shelf components allow us to provide cost-effective solutions for unique brake applications.

Wilwood is ISO 9000 compliant and has extensive experience maintaining quality levels of 100ppm or less for original equipment manufacturers.

Specifications:

| Kit Summary | |

| Axle Offset | 0.00 |

| Caliper Type | 4 - Type III Ano |

| Mount Type | Radial |

| Rear End Axle | OEM |

| Rotor Diameter | 12.19 |

| Kit Components & Specs / Rotors | |

| Bedded | No |

| Design Type | UL |

| Dynamically Balanced | No |

| Left Hand - Part No | 160-2895 |

| Material | Iron |

| Outside Diameter (in) | 12.19 |

| Style | Plain Face |

| Surface Finish | Plain |

| Type | 32 Curved Vane |

| Vane Count | 32 CV |

| Width (in) | 1.25 |

| Parts & Accessories / Caliper Parts | |

| Bleed Screw Kit | 220-0627 |

| Bridge Bolt Kit | 230-5978 |

| CrossOver O-Ring Kit | 130-10540 |

| O-ring Kit | 130-2427 |

| Replacement Piston 1 | 200-7550 |

| Replacement Piston 2 | 200-7551 |

| Wear Plate - Left Hand | 300-5923 |

| Wear Plate - Right Hand | 300-5922 |

| Kit Components & Specs / Hubs | |

| Bolt Circle 1 | Splined |

| Finish Color | Type III Anodize |

| Hub - Part No | 270-12633 |

| Material | Aluminum |

| Mount Style | Adapter-Dynamic |

| Type | Sprint Inboard Hub Kit - Dynamic |

| Kit Components & Specs / Calipers | |

| Brake Pad Area (In²) | 8.2 |

| Brake Pad Plate | 7420 |

| Brake Pad Volume (In³) | 4.9 |

| Finish Color | Type III Ano |

| Left Hand - Part No | 120-13264 |

| Mount Type | Radial |

| Pad Compound | BP-40 |

| Piston 1 Bore (in) | 1.88 |

| Piston 2 Bore (in) | 1.75 |

| Piston Area (In²) | 5.18 |

| Piston Count | 4 |

| Piston Type | Thermlock |

| Type | Forged Superlite 4 Radial Mount |