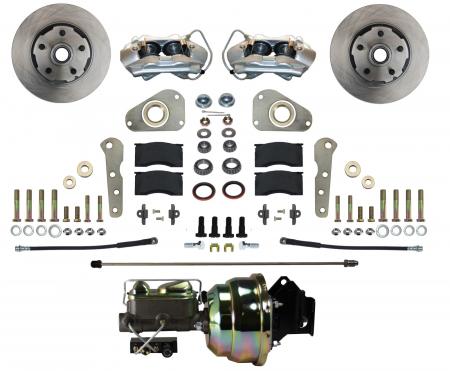

Wilwood's new DP-DB Pro-Series Front Hub Kits offer disc brake upgrade solutions for OEM spindles. We have completely redesigned our Pro Series line of brake kits using a larger 11" rotor and new forged aluminum hubs with the express purpose of maintaining the factory wheel position. Based on the venerable Forged Dynapro Dustboot caliper, these kits were developed for applications or locations that require or prefer a dust-sealed piston. Dust-booted aluminum pistons provide added protection against road or track born dirt and debris on low to intermediate temperature range applications that may also operate in harsh environments. Most vehicle applications require no modifications for installation, and provide plenty of clearance inside popular 15" wheels. DP-DB Pro-Series kits can be used with either manual or power boost master cylinders. Kits come complete with calipers, rotors, hub assembly, brackets and hardware. Kit installation requires purchase of additional brake lines shown below.

About Wilwood Engineering

Wilwood Engineering designs and manufactures high-performance disc brake systems. Since the company’s inception in 1977 by Bill Wood, we have developed a substantial matrix of brake components and engineering techniques that allow us to quickly and reliably create brake systems for almost any application. Our core ability is the rapid development of custom engineered brake systems using a combination of off-the-shelf and custom components. In addition to designing and manufacturing brakes for all types of competitive motor sports, Wilwood also manufactures brake systems and components for agricultural equipment, industrial applications, utility vehicles, snowmobiles, quads, motorcycles and military vehicles.

With headquarters in Camarillo, California, Wilwood employs approximately 250 people. We have on-shelf stock of more than 300 different brake calipers, 200 rotor designs, 100 master cylinder designs and a wide assortment of brackets, fittings, valves and brake lines. Our off-shelf brake calipers range in size from tiny calipers used on go-carts and light duty industrial equipment, to heavy duty original equipment brakes for the U.S. military Humvee.

Wilwood's engineering department uses the latest computer-aided design and manufacturing techniques in conjunction with finite element analysis, dynamic test and cycle test equipment, to find high-performance and reliability solutions for the most difficult braking tasks. Our extensive inventory of proprietary on-the-shelf components allow us to provide cost-effective solutions for unique brake applications.

Wilwood is ISO 9000 compliant and has extensive experience maintaining quality levels of 100ppm or less for original equipment manufacturers.